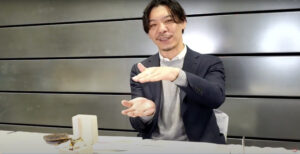

Since its establishment, the company has been making combs for 287 years. The combs are made from the finest Japanese boxwood and smoked for more than five years before they are finally ready for production. We interviewed Mr. Keiichi Takeuchi, the fifteenth generation owner of the long-established “Juso Yakushi Ten” about the process of making this gem of a comb, which can only be formed with a well-honed sense.

first partArticle by

We are located in Kagoshima, Japan, around Ibusuki and Mt. Kaimondake, and we only have boxwood cut in Ei Town. There is a cooperative over there, and now there are three houses. There are a lot of materials on the market, but to be honest, not all of them are from Japan.

Even though they are called boxwood, there are some that are made in Honyara.

Naturally, the texture and durability are different. We are particular about this and handle only the highest quality Japanese boxwood. Originally, boxwood was produced in Japan for a long time, and there were only four places in Japan where it was produced.(after past form of a verb) was just doingThere is only one. Since they were Edo craftsmen, there are boxwoods from what are now Mikurajima, Miyakejima, and Toshima in Tokyo. In addition, there is the boxwood of Kagoshima, which I mentioned earlier. There are only 4 countries in Japan.I can only get it in the

I see. There is talk that traditional crafts will suffer if the number of bearers of raw materials decreases, but I am grateful that there are people in Kagoshima who are making these products. It is really an important issue, isn’t it? I think it is thanks to them that we are able to maintain traditional crafts. So, you cut and pull the material with a circular saw, right?

That’s right. Then I polish the inside of each tooth one by one, which is called tooth polishing. So I sit and work all day long, just moving my hands in this way. I have never counted it myself, but a TV director once told me that I did it thousands of times to make a large comb. It’s a bit unique, and our method of making combs has basically not changed since the Edo period.

They all seem to be one-of-a-kind. Are you conscious of making them roughly the same shape?

Since the wood is expensive, at the purchasing stage, the size is determined by the cost, and the price per piece is determined by the cost. However, it is impossible to make a piece just in time. So, we made them in the traditional sizes of 2 to 3 minutes wide, or 6 to 9 millimeters. To put it roughly, we make them in small and fine increments of 6 to 9 mm, such as 4 x 2 mm, 4 x 5 mm, 4 x 8 mm, 5 x 5 mm, 5 x 3 mm, 5 x 5 mm, and so on.

Do you mean according to the size of the hand?

That’s right. In the past, we were in business with hairdressers in the Hanayagi community and other such places, so we had Sapporo and Hakodate in the north and Hakone in the northeast. The mountains of Hakone were quite steep, so our territory was from there to the northeast.

I see. There were limits to distribution, weren’t there?

In the past, craftsmen from Yabuhara in Kiso had the middle part as their territory, and craftsmen from Osaka had the southwest part as their territory, but now these barriers have disappeared. Conversely, since those barriers have disappeared, I thought I would explain later that the shape of these two pieces of comb is actually called the Higashi type, which is the shape of the Tokyo Edo period. This shape is called “Higashi kata,” which means “soft shoulders” when seen from behind. The western type is called the Naniwa type, and the shoulders are a little stouter than the eastern type. The difference between the two was clear. Nowadays, this eastern type is the mainstream throughout Japan because it looks good, but originally it was the Edo Tokyo style.

What kind of finish do you come up with after creating and polishing a shape like that?

After forming the shape, the surface is polished again with toksa, and the final step is to add luster with deer bones.

What are the benefits of deer bones?

Deer bone” is used to add luster.

The point is that the polishing is done at the stage when the toksa is done, but the luster is not. Therefore, in order to bring out the luster, the surface is crushed with a deer bone.

It is amazing that someone came up with the idea of using deer bones to bring out the luster, isn’t it? Today, we have three types of the finished product.

It is really a very small part of thousands of different types. The comb you use at home, the one with the finest grain is at the bottom, while the coarsest one is in the middle. The top one is called a set comb, which was introduced after the war. Women at that time used to curl their curlers before going to bed, so we adopted a completely Western shape to make it easier to use at that time. It has a vertical plate bar, so I just couldn’t make it in one piece. It’s a two-piece construction with the top part and the teeth part, and they are joined together.

You combine them.

Yes, it is. This is a comb for making back hair or doing fine work. If you come to us, we can tell you which one would be best for you according to your hair type, hairstyle, and amount of hair, etc. We also have a comb that you can actually use, so that you can buy it after you are satisfied with it. We have a variety of products that we can actually use for our customers, so that they can make a purchase only after they are satisfied with the product.

Now I would like to know what you think about the Jusan Yakushi brand.

Our combs are stamped with a small “jusan” (thirteen). We say, “If you see this, it is our comb and you can be sure of it. We are not ashamed of this engraving, and we make combs every day thinking that this is the equal of our brand.

Have you been doing that since about the first generation already?

It’s always been that way.

Do you bring things that your grandfather made and fix them?

Yes, there is. Look at this…” and so on.

Can you tell by looking at it whether this is the one from the previous generation or not?

I know what I am looking at.

That’s amazing. The old shop itself has been around for generations, but the customers have also been around for generations. When the name “Juso” is used, customers can already tell that it is Juso Yakushi-san. I think that is what a brand is all about.

We make products that do not shy away from the stamp on our products. It may be said that this pride is what has led the “Juso Yakushi Store” brand to this level. The business with a single comb will continue for the next 300 or 400 years.

*If you would like to see this dialogue on video.here (place close to the speaker or where the speaker is)