Nihonbashi (bridge)yukata (light cotton kimono worn in the summer or used as a bathrobe)

Founded in 1842, Shukusen is a long-established yukata manufacturer with 180 years of history. The company has continued to develop and produce yukata from the very first materials with a commitment to “make it yourself and sell it yourself. The high quality of yukata, which were popular among kabuki actors who were fashion leaders in the Edo period, continues to be loved by many people today. How are such yukata of “Shukusen” produced?I’d like to talk to Shigeyuki Ogawa.We visited.

Established in Asakusa and moved to Nihonbashi, popular yukata with chic designs

Hayashi: Today we will talk to Shigeyuki Ogawa of “Shukusen”. Please give him my best regards. First of all, please introduce yourself.

Mr. Ogawa: My name is Shigeyuki Ogawa of Jersey Shokusen Co. This year is my 16th year with the company, and although I was introduced earlier as the sixth generation, I am still in training.

Hayashi: If you do, please introduce your restaurant.

Ms. Ogawa: My name is Chikusen Corporation. Many of you may not be able to read the Chinese characters, but my name is “Chikusen,” which means “hermit’s hermit” in the Japanese character “zhu,” which means “a hermit’s hermit” in the Japanese character “tenzhu. Our company deals in yukata (summer kimonos), tenugui (hand towels), and furoshiki (wrapping cloths).

It has a history of 180 years since its establishment. The company was founded in Asakusa and its store is currently located in Nihonbashi. The founder of the company was very talented and became famous for his unique ideas and innovative designs. It is said that the Kabuki actors took a liking to his products, and they spread to the general public. Our stance of making things ourselves and delivering them to our customers has remained unchanged, and we continue to make things that fit the needs of the times.

Ms. Ogawa: An introduction of “Shukusen” can be found in “Tokyo Meibutsu Shi” published by Public Interest Inc. in 1901. It is clear that at that time, the company already had a reputation as “the head family of Shibuimono, and all connoisseurs would have known about it. We are truly grateful for this recognition, and we continue to make products that live up to the reputation of this reference.

Forest:It was in Asakusa when it was founded, wasn’t it?

Mr. Ogawa:Yes, I am. I heard that the company was founded in the area of Saruwakamachi in Asakusa. We have moved to Kobunacho in Nihonbashi, but in fact, we have a connection with Asakusa. There is a big lantern at Senso-ji Temple in Asakusa, and we have been offering it in Kobunacho for a long time. The name “Shukusen” is still on the back of the lantern, and we hope you will look for it when you visit Sensoji Temple.

Hayashi: Yes, I will definitely look for it.

And this picture shows the third generation of the head of the company serving customers. As the founder of the company, this third generation created many new things. Of course, he actually served customers himself, communicating with them and reflecting the results in his creations. There are other oral traditions such as “Shukusen’s Dyeing Frame Hitogara,” which was established and is still passed down today.

There is another one called Jyukusenkansei. We are told that this was also made during the third generation.

Whenever I purchase a yukata, this paper is always included.

Ms. Ogawa: Thank you very much. We always put a piece of paper saying “Made by Shukusen-kan” on our products to indicate that they have passed through our owner’s eyes and are not ashamed of being released to the world.

Hayashi: When it comes to yukata, you may know how they are made, but you don’t know, do you? Today, I would like to ask you to tell us again.

The process of making yukata by the technique of “Shizome

Yukata made by the “chusen” technique is the most popular traditional dyeing method, including the price range. First, a design engraved on Japanese paper is applied to a pure white fabric.

Hayashi: So the original is white fabric?

Ogawa:Yes. The first process is called “glue placement,” in which antistaining glue is placed on top of the fabric using a wooden spatula. Next comes multicolor dyeing. If we want to use different colors, we make a border with glue to prevent the dye from getting into the fabric.

So you are putting glue on the parts that should not be dyed. You can see how much time and effort went into this.

And then there is “Koya”. This is the dyeing process. Using a jar-like container filled with dye, the craftsman pours the color into the container while looking at a sample. Since there are several layers of fabrics that are about the same size as two sheets of fabric, it is the skill and experience of the craftsman that allows the dye to penetrate to the bottom of the fabric.

So you have to put in the right amount. It’s very difficult.

Then, it is “rinsed in water. The excess material such as glue applied at the beginning is removed.

So this is another reason not to wash too much.

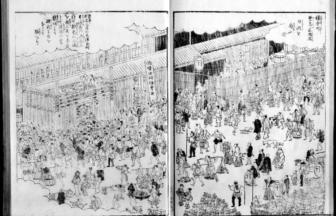

Ms. Ogawa: Yes, that’s right. Because the dye will come out. Then comes the “dara-hai” (drying in the sun). As shown in old ukiyoe prints, it is an important process to dry the fabric from a high place like this in the sun.

So much hard work goes into the process before you see a fabric made by Jyukusen.

I have introduced the “hoshizome” technique, which has many processes, although it is really only a rough sketch.

I also have a yukata by Jyukusen, and not only is the dyeing excellent, but the feel is also very good. Please introduce this material as well.

Ms. Ogawa: “Coma fabric” is our most basic material. In the past, yukata were made of “okamomen,” a slightly thicker cotton yarn. This in itself is not a bad thing, but “combed fabric” is a more refined version. The yarn that has gone through the process of burning off fluff is called “combed yarn,” and the fabric in which the combed yarn is beaten is Shukusen’s “combed fabric. Because the fluff has been removed, the fabric is much more comfortable to touch and wear, and above all, the dyeing process is very beautiful.

How many days does it take to start with white dough?

We don’t follow just one warp all the time, but work on several pieces of the same process in parallel. Also, in order to eliminate waste, we do it all together on the same day when the same dye is used, so it is impossible to say how many days it takes. However, if we simply place the molds, insert the dye, and bring them to the final state of washing, the time calculation might be about one day. Of course, after that, there are processes that depend on the weather, such as drying in the sun.

When does the work season begin?

We do more or less work depending on the time of year, but as far as pour-dyeing is concerned, we do it throughout the year. For yukata (summer kimonos), work begins in the summer of the previous year.

I see…you have been working on it for a year.

From the history of Jyukusen, we learned how many processes are involved in making a Jyukusen yukata. In the second part, we will talk further about the types of materials and manufacturing methods.

latter part(temporal or logical sense) follow …

*If you would like to see this dialogue on video.here (place close to the speaker or where the speaker is)