Nihonbashi (bridge)cleaning utensilsEdo broombroom

Shirokiya Nakamura Denbei Shoten, founded in 1830, is a long-established company that makes Edo brooms, which are made by weaving grass by hand.Without electricity,pOld-fashioned cleaning tools that do not use rustic are items that are attracting renewed attention in this age of SDGs. Suchwhich has been making Edo brooms for generations.Masakatsu Hayashi, representative of Starmark Corporation, which operates “agataJapan tokyo,” spoke with Satoru Nakamura, the seventh generation owner of “Shirokiya Nakamura Denbei Shoten.

Edo broom made using the same manufacturing method since its establishment

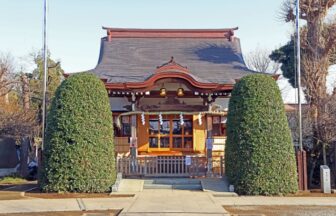

Mr. Nakamura: I am the seventh generation representative of a grass broom manufacturer called Shirokiya Denbei, located in Kyobashi 3-chome, Chuo-ku, Tokyo. There are two types of brooms, one made of shuro and the other made of grass, and the grass broom was created in Edo in the latter half of the Edo period. The grass broom was created in Edo in the latter half of the Edo period (1603-1868), and has been made from generation to generation.

Mr. Nakamura:The original materials are combined and knitted together to make the product. The method of production has remained almost unchanged since the company’s founding in 1830.

Mr. Nakamura:The original technical level of the product is so high and very complete that there is still no need to add or subtract anything. In recent years, we have also made smaller brooms for apartment dwellers and elderly people. We have also made a broom with a 10 cm longer handle than our previous brooms because more and more tall men want to stop using vacuum cleaners and use brooms for cleaning. However, the characteristics of the Edo broom are that it is soft, resilient, easy to scrape off, and lightweight. The craftsman said, “If you make it 10 cm longer, it won’t have the best balance.

Mr. Nakamura:However, we managed to persuade them to make a prototype. When we put them on display in the store, tall customers bought them, saying, “Isn’t this easier? and they bought it. When the prototypes sold like that, the craftspeople thought, “What the heck” (laughs). (Laughs.) I still haven’t received an OK from Kashira, the craftsman, for the completion of the product. The process of trial and error has been going on for a long time.

Ms. Nakamura: Yes, that’s right. The other thing is “efforts not to regress” in terms of how much the current situation can be maintained at the current level. This is true technologically as well as in terms of efforts to secure high-quality materials. That is something we cannot do without looking about 10 years into the future, so we are working on that in parallel, including securing human resources.

Ms. Nakamura:Broomsticks are ranked according to the weaving method. The one on the right is called “domono,” which is made by weaving large parts together. The type with a window on the left side uses more grass, so it uses a technique of cutting off the edge to make it lighter. We call it the “new type,” but it was made in the early Showa period (early 20th century). Both types are made of domestic grass, and the right one costs 35,000 yen and the left one 70,000 yen.

Mr. Nakamura:Domestic grass is only available once a year, so we use year-round grass from Thailand and Indonesia, which can be triticale. Our craftsmen select only the soft and elastic brooms from among the broom grasses to make our brooms. Brooms made from soft and pliant grass require less effort and sweep better. When you sweep the broom, you will feel the elasticity and the bounce of the tip, similar to that of a brush.

Mr. Nakamura:It is very difficult to determine the rank of grass immediately after becoming a craftsman. At first, we have our craftsman Kashira, who has absolute finger feeling, sort the grass; after making about 1,000 pieces, he will be able to tell the rank of the grass with his finger, and after making another 1,000 pieces of the next rank of grass, he will be able to tell the difference between the first and the next rank of grass.

Mr. Nakamura:When you make all 10 or so types of brooms in this way, you will be able to tell the difference between all of them. The best of them will specialize in sorting the brooms. Weaving can be done in one or two years, but sorting is not something you can teach, but something you learn. Therefore, it takes at least 10 years of work to understand the difference between the two, and it is not something that can be done by a lowly worker.

Mr. Nakamura:Even if the hardness and elasticity of the grass are the same, the softness of the tip will be different at different ear lengths. So, what is the main point to look for? That is how you can tell. No matter what the length, it is all the same there. So it is a process of learning that sensation with your fingers.

Mr. Nakamura: Yes. They are not all the same, so we choose as many as we can cut together with the right rank.

Why did we insist on domestic production even when it became difficult to secure raw materials?

Mr. Nakamura:Until about five years ago, we used to have a man named Mr. Kounosu from the former Oho village in Tsukuba, Ibaraki Prefecture, make them for us, but he became ill and was no longer able to do so. Since all the work is done by hand, ordinary farmers don’t do it because they find it too tedious.

Mr. Nakamura:At that time, our manager went there for a year to learn how to grow broom grass and acquired the know-how. However, we could not do that every year, so we went to Chuo City to ask them to introduce us to farmers who could grow the broom grass we wanted. I asked the JA of Higashine City in Yamagata Prefecture, which is a friendly city of Chuo Ward, and found several farmers who were willing to grow it. The price was quite expensive, but we decided to give it a try anyway.

Mr. Nakamura: The reason why we need to use domestic grass is that Thai and Indonesian grass has different elasticity from domestic grass. Customers who have been accustomed to domestic grass for a long time already remember it with their fingers, so when we serve foreign grass, they say, “Isn’t this grass a little different? When we serve foreign grass, they say, “This is a little bit different. For those customers and for the mission of preserving the products from the time of the company’s establishment, we ask our customers to produce domestic grass on purpose.

The Edo broom, which has been made in the same way since its establishment and passed down from generation to generation, has a history of difficulties in securing raw materials, and we can glimpse Mr. Nakamura’s spirit of preserving tradition in this. In the second half of the interview, we will hear about the training of craftsmen and maintenance of brooms.

⇒latter part(temporal or logical sense) follow …

*If you would like to see this dialogue on video.here (place close to the speaker or where the speaker is)