Since its establishment, the company has been making combs for 287 years. The combs are made from the finest Japanese boxwood and smoked for more than five years before they are finally ready for production. We interviewed Mr. Keiichi Takeuchi, the fifteenth generation owner of the long-established “Juso Yakushi Ten” about the process of making this gem of a comb, which can only be formed with a well-honed sense.

We are pleased to have with us today Mr. Keiichi Takeuchi, the fifteenth generation owner of the Juso Yakushi Restaurant. May I ask you to introduce yourself?

My name is Keiichi Takeuchi, and the name of my restaurant is Juso Yakushi-ten. I am the fifteenth generation there. I started working after I graduated from high school in 1986. Since it was my own family, everyone around me told me that it would be a waste if I did not take over the business, and in fact, my father never told me to take over the business, but I decided to take over and started my training.

At what age did you start your training?

I didn’t officially start working until after I graduated from high school, but in reality, I had no allowance when I was in junior high school, and I was forced to do some kind of physical training, such as paying how much it costs to polish one comb.

It’s the kind of style where you get an allowance for helping out, isn’t it? You had a lot of opportunities to come into contact with your family’s business from when you were a child, and you were already thinking in junior high school that you might somehow take over the business?

When I was a small child, it was a matter of course. Since my work place and home were the same, when I came home after school or kindergarten, I would go to my work place and peek in, and I was completely a kid at the front gate. So, I think I had three or four advantages over those who started from scratch.

Next, I would like to ask you to introduce your restaurant.

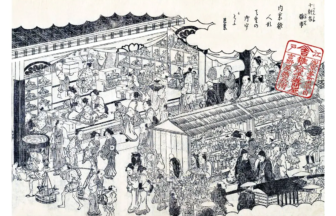

It is located in Ueno, Tokyo, which used to be called Ikenohata, and has been operating a single boxwood comb business for 287 years since 1736 at the same location.

The current location of the store will stay where it is now? That’s great, it’s a crazy good location.

No, no, it is a nice place now, but it used to be actually a back alley. Shinobazuno Pond is right in front of it, but after the Great Kanto Earthquake of 1932, when the area was rezoned, it became a main street right in front of it. It may seem like a nice place, but it used to be a back street.

I see. When I visited there, the lotus blooming on Shinobazu Pond was very beautiful. You have such a view right in front of your eyes. May I ask what kind of products you have been selling for the past 15 generations?

Preserving work unchanged since the Edo period.

Of course, boxwood combs. We do everything from the very beginning, from procurement to processing, and from the start of processing to the finished product. Of course, some parts are mechanized, but the work of making the inside of the teeth has not changed at all since the Edo period.

May I ask how you actually go about making it?

This part of the stick is tokusa (a plant called tokusa), and I have the one before pasting and the one with grains. This is the grainy one, and this is the thinly skinned one, which is boiled slowly like a dish to soften it, and then the streaks are removed and stuck to the stick with rice-grain paste.

What is this thin board itself based on?

This is a cherry tree.

What kind of trees?

No, boxwood is a hard and dense wood, but something softer than boxwood, which is almost always the case, would fight and ruin the toksa if done with the same material, so a slightly softer wood is better.

It’s like a grain of rice on a cherry tree, isn’t it? With a grain of rice on a cherry tree?

For example, if a piece peels or breaks off and needs to be replaced, it can be easily removed by soaking it in hot water. If you wipe it off, knead some rice grains and stick it back on again, and it’s back to normal.

So, if you make one of these tools, do you feel that you can use it for a rather long time?

Yes, you can make roughly 30 sheets per paste.

Is it roughly a month or so to make 30 sheets?

30 sheets would be about 10 days.

Will the surface toxa be ruined?

It will not be able to be cut.

Are you saying that the trees are fine, but you will replace the toxa?

Yes, it is.

Like the sauce at an eel restaurant, do you use a stick that has been in use for five or six generations?

No, there is such a thing. A comb maker is a very difficult profession. A comb shop can only make combs. So, for example, when a craftsman goes out of business, quits, or passes away, if there is no heir, we buy the tools he used, modify them a little to make them easier for ourselves, and then we remake the tools and use them again and again. That is why the tools I am using now are so old that I don’t even know who used them.

That’s amazing. So you are making your products with such a long tradition. What is the first step in the process?

Since toksa is the last step in the polishing process, sharkskin is initially stretched over a similar material. Shark skin is often used to grate wasabi, right? Shark skin is very suitable for rough grinding. I use the shark skin to make a rough shape. There is still some roughness, so we file it with a steel file. Then I polish the inside of the comb one by one with a toxa stick.

It looks like a kamaboko board!

At first, we have the cutting edge and the back of the wood milled in this condition. If the wood is still raw and left to sit for a number of years, when it is made into combs, the raw wood will return to its original state, and it will become rough and ruined. In order to calm it down, boxwood is smoked to remove the scum, as you can see here in the black color.

Acne removal! It looks kind of tasty (laughs).

Raw materials must be laid down for at least 5 years to be useful.

Only after we give them the scum, they are finally dried naturally, in our case for at least 5 years, or a little more depending on the size.

I guess you have to let it sit for a long time after removing the acridity. 5 years is amazing. Is the warehouse pretty full?

Yes, I already have a whole house full of them piled up.

Oh, was this the fourth year, or was it the third year? …… or do you lose track of that kind of thing?

I have already tagged all of them properly. If you don’t do it right, you won’t be able to tell.

Like whiskey, is there a certain number of years old that is good?

I am often asked if it is better to let the wood rest for a while, but that is not the case. If the wood is not dense, it is called “stove-dried,” and if you put it in a room and dry it with a stove, it will dry inside. However, boxwood is a very dense wood, so even if you do that, you can only remove the moisture from the surface. Therefore, it takes at least five years to dry the wood slowly over a long period of time. If this treatment is done, for example, the material will not be damaged even if it is left for 50 years before it is made.

Wow that is amazing.

However, if they are left in a near-raw or raw state, they will still be ruined.

Is it not good enough to lose water?

It’s been said for a long time that if you smoke it, it will be fine. In fact, the weight is totally different.

So you process them. This is the only mechanized process, and it involves attaching teeth with a saw.

We pull them one by one with a circular saw.

You say, “I’m going to pull it.

Juso Yakushi Store” boasts a history of 287 years with a single comb. The secret seems to lie in the careful craftsmanship that goes into each and every product. It is not an easy task. Nevertheless, the fact that they have never given up their persistence has led to their firm position as a comb shop.

latter part(temporal or logical sense) follow …

*If you would like to see this dialogue on video.here (place close to the speaker or where the speaker is)